在线订购说明

为保障消费者权益,真正做到正品交易,杜绝假冒伪劣产品

除电话订购外,本产品支持 阿里巴巴诚信通 支付宝交易。

阿里巴巴店铺地址: http://songhanplas.1688.com

可以与公司客服沟通进行线上交易。

除电话订购外,本产品支持 阿里巴巴诚信通 支付宝交易。

阿里巴巴店铺地址: http://songhanplas.1688.com

可以与公司客服沟通进行线上交易。

相关物性索引

|

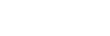

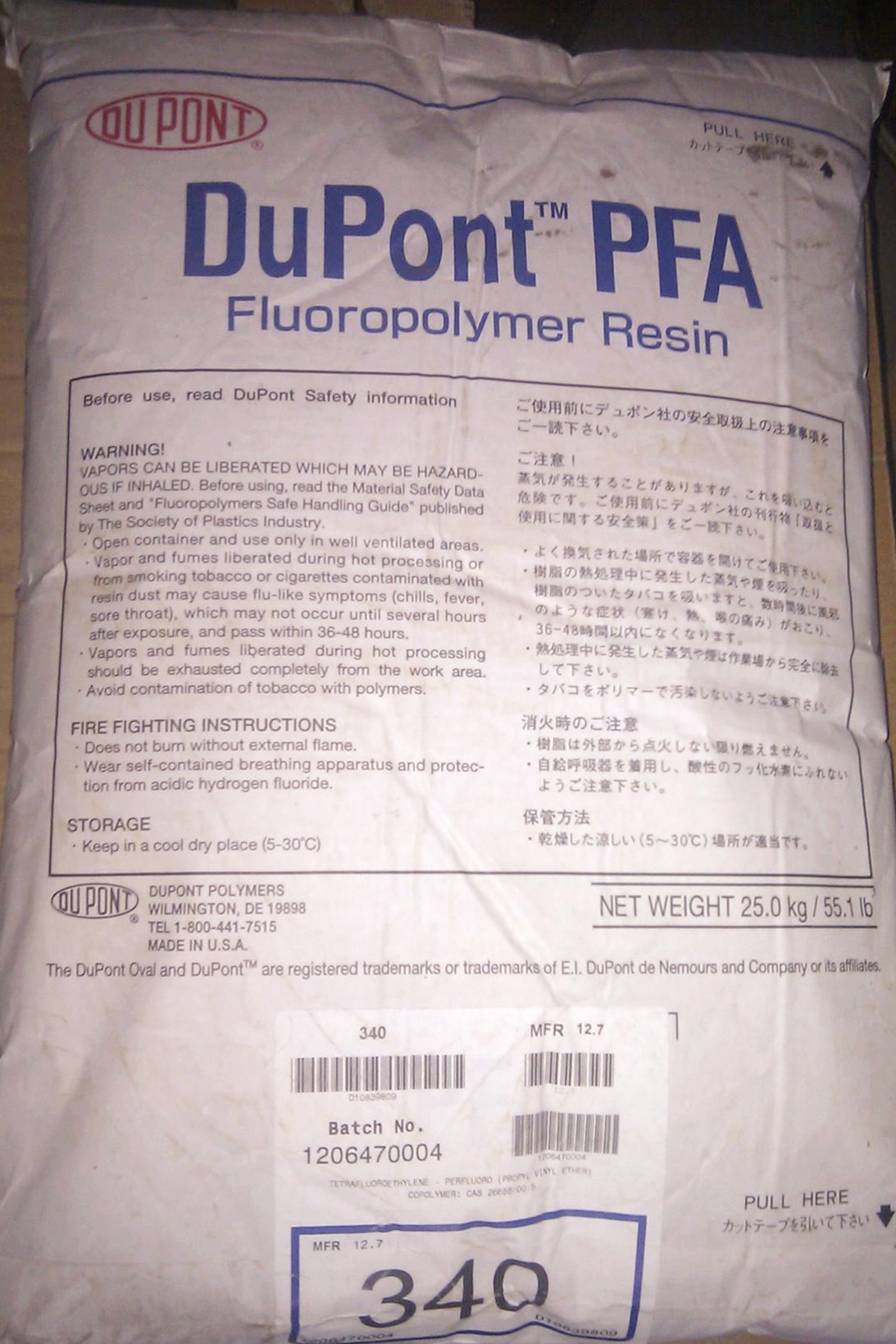

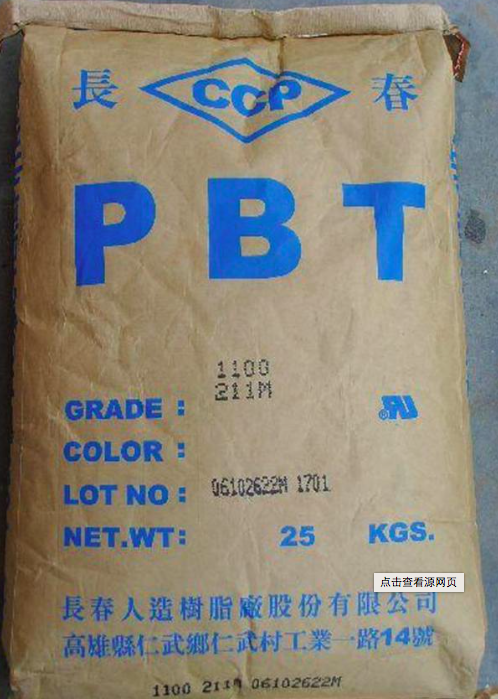

材料标识 : PFA-V0,颜色 : 本色/Natural colour,厂商品牌 : Teflon ,用途 : 衬里 管道 液体处理,材料特性 : 低摩擦系数 吸潮性差 烟释放低良好的柔韧性 流动性低 耐化学性良好 耐气候影响性能良好 耐热性中等,材料形状 : 颗粒状/Resin,加工方式 : 注射成型/Injection molding 挤出成型/Extrusion molding 树脂传递成型/Resin transfer molding, (更多..)

|

|

For inventory control purposes product name may be followed by an X.

Products labeled PFA 945HP Plus and PFA 945HP Plus X are equivalent and all information in this document is applicable to both. Typical Application With a typical MIT folding endurance of 800,000* cycles, DuPont™ Teflon ® PFA 945HP Plus is designed to withstand repeated flexing and aggressive chemical stress-cracking agents. Applications for Teflon ® PFA 945HP Plus include fluid handling components for high-performance chemical delivery systems, as well as tubing, unsupported pipe linings for the production of ultra-pure chemicals, and semiconductor components where purity in the parts-per-billion range is critical. Description DuPont™ Teflon ® PFA 945HP Plus is a premium fluoroplastic resin available in pellet form. Teflon ® PFA 945HP Plus possesses the same exceptional chemical resistance, high purity, and protection against ionic contamination as Teflon ® PFA HP grades with the added benefits of improved flex life (typical MIT flex of 800,000*) and chemical stress-crack resistance. Teflon ® PFA 945HP Plus meets the increasingly stringent requirements for ultra-reliable and non-contaminating parts, as well as unmatched HCl permeation resistance. The improved flex life and chemical resistance will reduce the cost of ownership of high purity fluid handling systems by reducing downtime caused by mechanical or chemical stresses. Additionally, parts molded with Teflon ® PFA 945HP Plus have improved clarity and a smooth finish, which can further help prevent buildup of microbial contamination in water handling systems. Table 1 shows the typical property data for Teflon ® PFA 945HP Plus. This special purpose resin has a mid-range melt flow rate (typical MFR of 7), which permits relatively high extrusion speed and easier processing. The enhanced resistance to environmental stress-cracking makes Teflon ® PFA 945HP Plus a preferred resin when extended service is required in hostile environments involving chemical, thermal, and mechanical stress. Additionally, the enhanced purity of Teflon ® PFA 945HP Plus makes it suitable for applications that require improved color, lower extractable fluorides, and freedom from other foreign materials. This product contains no additives and is designed for hostile chemical environments where purity in the parts-per-billion range is needed. Examples are in semiconductor manufacture, fluid handling systems for industry or life sciences, and instrumentation for precise measurements of fluid systems. Teflon ® PFA 945HP Plus combines the processing ease of conventional thermoplastics with the properties similar to those of polytetrafluoroethylene. With Teflon ® PFA 945HP Plus, components can last longer under dynamic loads and resist damage caused by ozonated fluids and fluorosurfactants. Combined with excellent chemical, permeation, and stress-crack resistance, this durability leads to a reduced cost of ownership. The high purity and fully fluorinated olecule end groups of Teflon ® PFA HP Plus can reduce contamination to protect process yields. Properly processed products made from neat Teflon ® PFA 945HP Plus resin provide the superior properties characteristic of fluoroplastic resins: chemical inertness, exceptional dielectric properties, heat resistance, toughness and flexibility, low coefficient of friction, non-stick characteristics, negligible moisture absorption, low flammability, performance at temperature extremes, and excellent weather resistance. In a flame situation, products of Teflon ® PFA 945HP Plus resist ignition and do not promote flame spread. When ignited by flame from other sources, their contribution of heat is very small and added at a slow rate with very little smoke. Teflon ® PFA 945HP Plus meets the requirements of ASTM D3307, Type VI (更多..) |

详细数据

订购指南

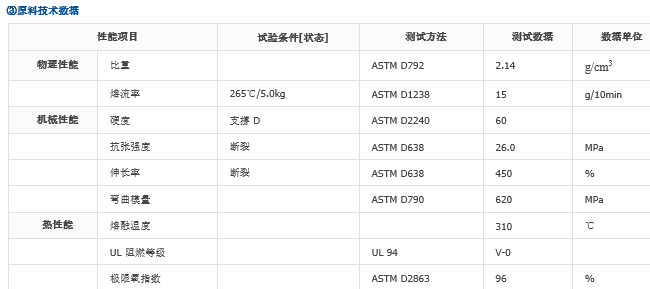

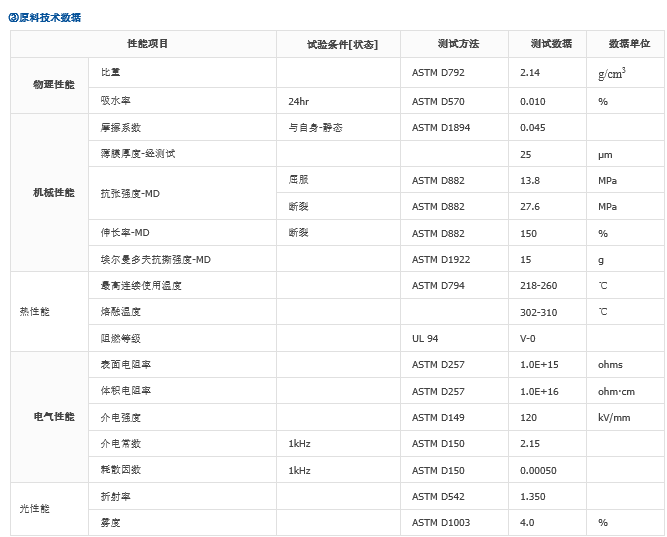

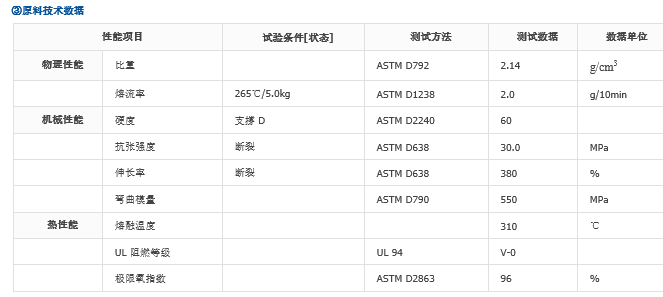

重要参数: 密度:2.14 g/cm3 吸水率:0.03 % 弯曲模量:689 MPa 硬度:60 热变形温度:47.8 ℃ 脆化温度:-196 ℃

特性备注:阻燃,良好的耐化学性,良好的导电性能,高耐热,半结晶

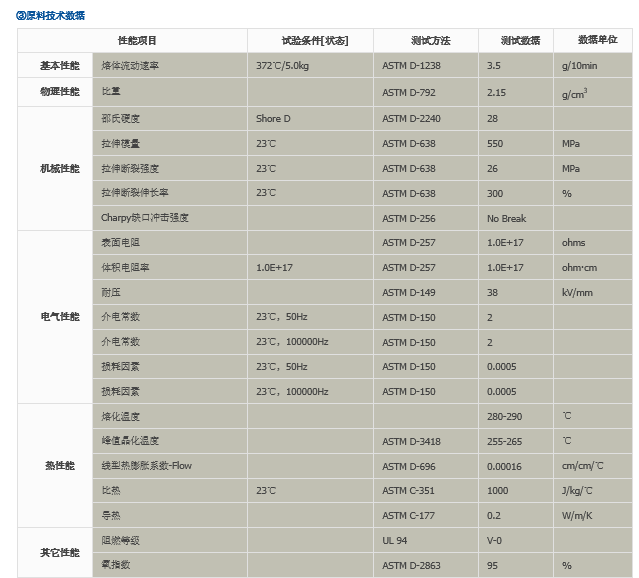

重要参数: 熔体流动速率:3.5 g/10min 密度:2.15 g/cm3 氧指数:95 % 拉伸强度:26 MPa 断裂伸长率:300 % 硬度:28

特性备注:阻燃,良好的耐化学性,良好的导电性能,高耐热,半结晶

重要参数: 熔体流动速率:3.5 g/10min 密度:2.15 g/cm3 氧指数:95 % 拉伸强度:26 MPa 断裂伸长率:300 % 硬度:28