在线订购说明

为保障消费者权益,真正做到正品交易,杜绝假冒伪劣产品

除电话订购外,本产品支持 阿里巴巴诚信通 支付宝交易。

阿里巴巴店铺地址: http://songhanplas.1688.com

可以与公司客服沟通进行线上交易。

除电话订购外,本产品支持 阿里巴巴诚信通 支付宝交易。

阿里巴巴店铺地址: http://songhanplas.1688.com

可以与公司客服沟通进行线上交易。

相关物性索引

|

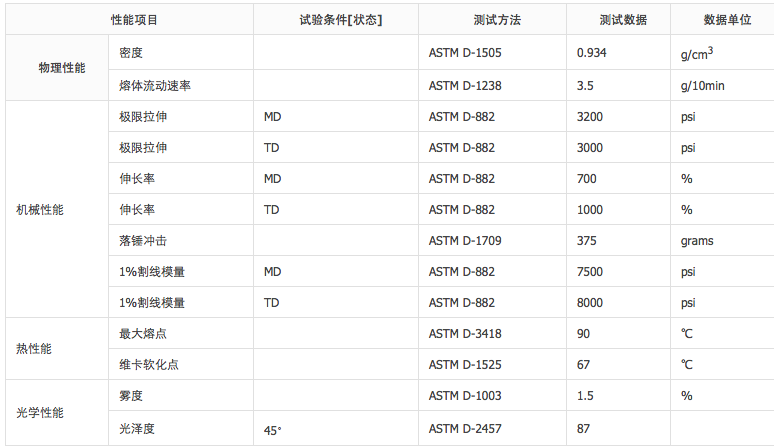

材料标识 : EVA,颜色 : 本色/Natural colour,厂商品牌 : HANWHA ,用途 : 泡沫、生活消费品 和 食品接触应用,材料特性 : 加工性能良好、醋酸乙烯含量 26.0 wt%,材料形状 : 颗粒状/Resin, (更多..)

|

|

断裂伸长率 : 900%,拉伸强度 : 13MPa,密度 : 0.949g/cm3,熔体流动速率 : 3g/10min,硬度 : 28,规格级别 : 发泡,加工级别 : 发泡级,用途:各种发泡成型的应用,如鞋和凉鞋等

备注:良好的发泡成型性能、非常良好的机械性能、优秀各种填料加载性能、良好弹性海绵

(更多..)

|

|

BLS® 1326 is a benzotriazole type ultraviolet light absorber (UVA), imparting good light stability for plastics and other organic polymers. BLS® 1326 is especially suited for polyolefins and cold cured polyesters. It protects polymers from UV radiation helping to preserve the original appearance and physical integrity, especially for polyolefins and polyester resins.

Applications: BLS® 1326 is especially suited for polyolefins and cold cured polyesters. In polyolefins, it has a low volatility at high temperatures and high resistance to thermal degradation for polyolefin compounding and molding applications. For best results, it should be used with a HALS type light stabilizer. In polyester resins, BLS® 1326 does not form colored complexes with metallic curing salts. It is also good with chlorinated flame-retardant polyester resins. Advantages:

|

|

HANWHA EVA 1326 is manufactured by Dow autoclave high pressure process and designed for variety of foam molding application such as shoes and sandals etc. EVA 1326 is well known for its excellent processability and high quality assurance. (更多..)

|

|

INNOPOL® CS 1-3260 is a 55 % chalk-filled polypropylene homopolymer compound /PP-H KD55 (ISO 1043)/.

INNOPOL® CS 1-3260 is developed for producing injection moulded components for household equipments. (更多..) |

详细数据

订购指南

| 数据提供企业[上海市SongHan Plas塑胶原料有限公司 ] | |||||

| 性能项目 | 测试条件 | 测试方法 | 数值/描述 | 单位 | |

| 机械性能 | 拉伸强度(引张强度) | ASTM D638/ISO 527 | kg/cm²(MPa)[Lb/in2] | ||

| 断裂伸长率 | ASTM D638/ISO 527 | % | |||

| 拉伸模量 | ASTM D638/ISO 527 | kg/cm²(MPa)[Lb/in2] | |||

| 拉伸屈服伸长率(延伸率) | ASTM D638/ISO 527 | % | |||

| 拉伸断裂伸长率(延伸率) | ASTM D638/ISO 527 | % | |||

| 弯曲模量(弯曲弹性率) | ASTM D790/ISO 178 | kg/cm²(MPa)[Lb/in2] | |||

| 弯曲强度 | ASTM D790/ISO 178 | kg/cm²(MPa)[Lb/in2] | |||

| 硬度 A | ASTM D2240/ISO 868 | Shore A | |||

| 硬度 D | ASTM D2240/ISO 868 | Shore D | |||

| 落球冲击强度 | ASTM D1709 | g | |||

| 洛氏硬度 | ASTM D785 | ||||

| 物性性能 | 比重(密度) | ASTM D1505 | 0.941 | g/cm³ | |

| 熔融指数(流动系数) | 200℃/5kg | ASTM D1238/ISO 1133 | g/10min | ||

| 220℃/10kg | ASTM D1238/ISO 1133 | g/10min | |||

| VA含量 | 18 | % | |||

| 热性能 | 热变形温度 | 退火 | ASTM D648/ISO 75 | ℃(℉) | |

| 未退火 | ASTM D648/ISO 75 | ℃(℉) | |||

| 维卡软化点 | ASTM D1525/ISO R306 | 64 | ℃(℉) | ||

| 熔点 | - | 88 | ℃(℉) | ||

| 电气性能 | 介电常数 | 100HZ | ASTM D150/IEC 60250 | ||

| 1MHZ | ASTM D150/IEC 60250 | ||||

| 体积电阻率 | ASTM D257/IEC 60093 | Ω.cm | |||

| 表面电阻率 | ASTM D257/IEC 60093 | Ω | |||

| 耐电弧性 | ASTM D495/IEC 60112 | ||||

| 光学性能 | 透光率 | ASTM D1003/ISO 13468 | % | ||

| 光泽度 | ASTM D2457 | ||||

| 加工条件 | 干燥条件 | ||||

| 加工温度 | 射嘴 | ℃ | |||

| 料筒前段 | ℃ | ||||

| 料筒中段 | ℃ | ||||

| 料筒后段 | ℃ | ||||

| 熔体温度 | ℃ | ||||

| 模具温度 | ℃ | ||||

| 压力 | 注塑压力 | Mpa | |||

| 保压压力 | Mpa | ||||

| 背压 | Mpa | ||||

| 螺杆转速 | rpm | ||||

| 其他 | 备注 | ||||

| 颜色 | |||||

| 特性 | 耐寒性较好,共聚物,较好的韧性,良好的灵活性,弹性。 | ||||

| 用途 | 鞋类,玩具,油管,体育用品,食品包装 挤压,发泡,注塑成型 | ||||